High Energy Laser (HEL) Optics Demand Precision Cleaning!

What Are They?

High-Energy Lasers are used in both commercial applications and Directed Energy Weapons (DEW) for the Department of Defense, and the optics in these HEL systems demand precision cleaning.

Why is Cleaning HEL Optics Important?

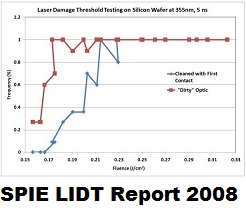

Read the report below. For HEL system optics to deliver outstanding laser damage threshold, ultra-low scatter, and excellent wavefront performance they must be cleaned to the molecular level with no residue or contamination present and befree from potential damage resulting from contact cleaning processes to insure a long, useful operational lifetime. Extrinsic damage involving optical absorption by opaque nanoscale and microscale defects, such as particulates and contaminants, occurs because of poor cleaning protocols resulting in surface scratches and digs.

Laser Induced Damage due to contamination and surface defects from cleaning processes

How Should I Clean My HEL Optics?

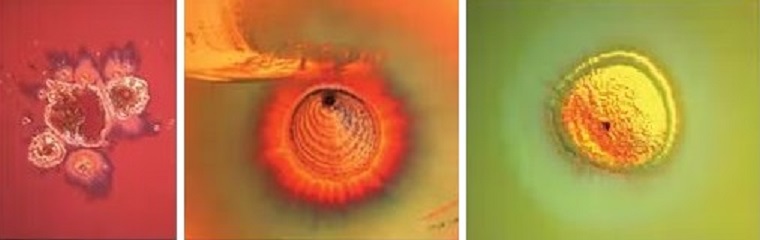

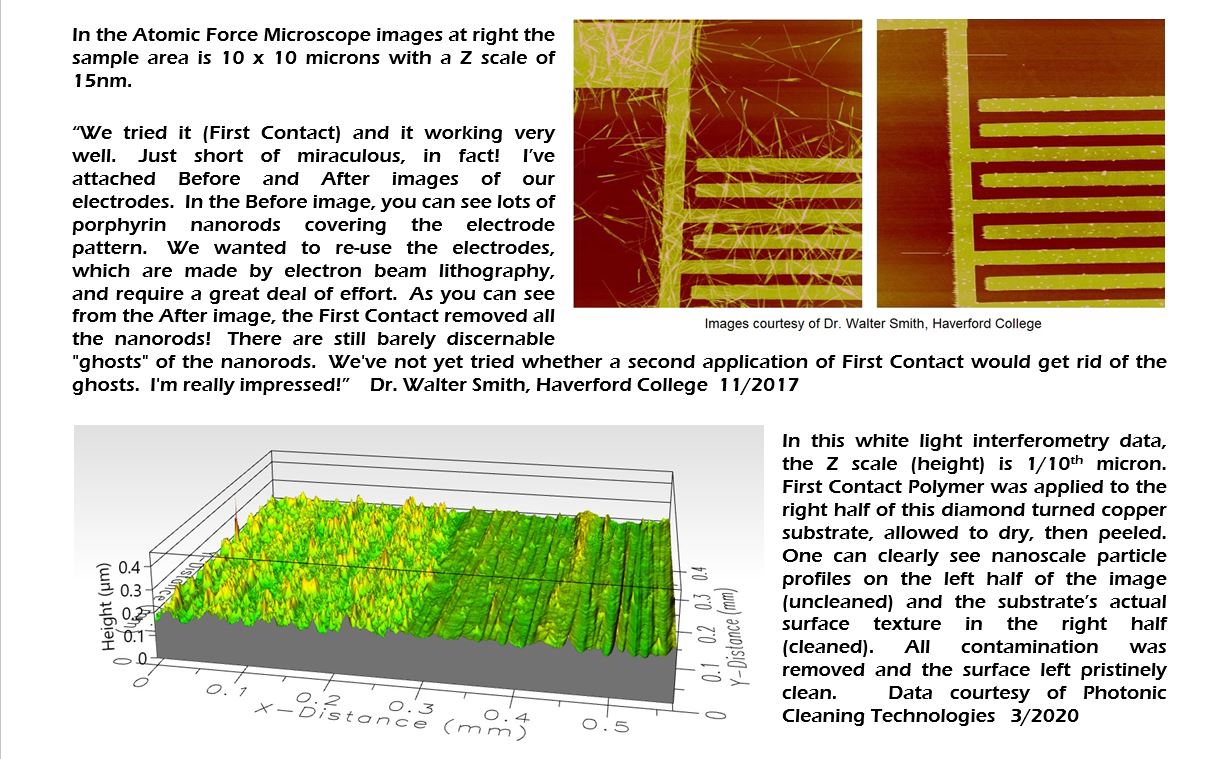

First Contact Polymers clean to the molecular level and remove nano-scale particulates which are damaging to HEL optics. The images below are evidence of nano-scale particle removal and such cleanliness levels have been verified by many outside sources as described in this document showing No Residue via ESCA/XPS from NASA, LIGO, and Others.

Laser Induced Damage Threshold (LIDT) Testing

Our First Contact Polymers have also been tested and evaluated by independent laboratories for LIDT reduction for fluence, intensity, and wavelength. Review these documents for LIDT test results and additional data:

aaaaaaaaaaaaaaaaaaa aaaaaaaaaaaaaaaaaaa

"Conclusions: In this paper, the cleaning method of First ContactTM to the surface of optical thin films is studied experimentally. The test results of the microscope and the intra-cavity device reveal that, the cleaning effect of First ContactTM is perfect, and there are no negative effects, such as pollution and damage. But the defects of substrates or optical films can not be repaired by First ContactTM. The layer of First ContactTM can be torn off completely even 3 months after spraying, so it may be used for protecting optical components when preservation and transportation."

|