Cleaning Coated Laser Optics and Diffractive Optics

First Contact™ Polymer is the world's first strip coat cleaner that safely cleans coated laser optics. First Contact follows surface contours, dissolves organic contaminants, and encapsulates particulates as it dries to a robust film. Peeling the polymer film renders the surface pristinely clean! Read the report below.

Why Use First Contact?

- Cleans contaminants and nano-particulates from precision optics

- Removes fingerprints

- Leaves no residue

- Removes residue from other cleaning processes

- Leaves optical thin films intact on optics, mirrors, and diffraction gratings

- Physically protects optics from airborne contaminants and accidental contact

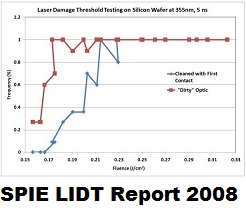

Laser Induced Damage Threshold Testing

The polymers in First Contact have been tested and evaluated by independent laboratories using many techniques. Review the following documents with

laser induced damage threshold (LIDT) test results and additional data:

aaaaaaaaaaaaaaaaaaaaaaaa aaaaaaaaaaaaaaaaaaaaaaaa

First Contact Polymer Test Study:

"Conclusions: In this paper, the cleaning method of First ContactTM to the surface of optical thin films is studied experimentally. The test results of the microscope and the intra-cavity device reveal that, the cleaning effect of First ContactTM is perfect, and there are no negative effects, such as pollution and damage. But the defects of substrates or optical films can not be repaired by First ContactTM. The layer of First ContactTM can be torn off completely even 3 months after spraying, so it may be used for protecting optical components when preservation and transportation."

|